This topic has been fairly quiet of late, so am adding some info so that it stays near the top.

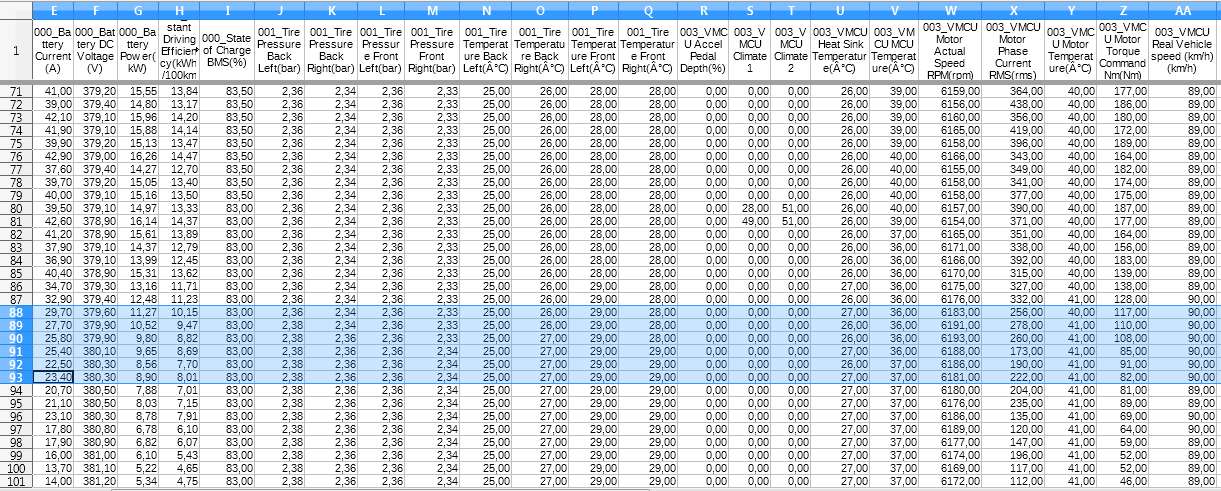

Development of the Soul Spy app seems to have paused, so in the meantime I am using the Torque Pro app to get OBD readings from my car.

Soul Spy - https://github.com/pemessier/SoulEVSpy

Torque - http://www.mykiasoulev.com/forum/viewtopic.php?f=6&t=471

This thread has also been used in the past for analysing the CANBUS. I am currently looking for the temperatures values for the OBC and a value that shows when the Electric Water Pump comes on. Anyone know? Currently I have to watch the value for the VMCU heatsink temperature and listen to the sound to hear when the heat pump comes on and off. It would be easier to log this automatically if we had the PID codes. What I have found so far is that the OBC heats up quite fast during charging. The EWP comes on at 47C and quickly cools the OBC back down to 35C when it shuts off.

I am using a Konnwei KW902 OBD adapter. I have now added an OBD extension wire with a switch. This solves the possible problems that the KW902 has. 1/drawing power when the car is off. 2/having an insecure password.

Tonsiki OBD 2 Cord 16 pin M/F Male to Female Right Angle Diagnostic Extension Cable with Power Switch to avoid battery drain

I pushed the OBD connector back out of its clip to allow room for the plastic cover to be closed. The OBD extension wire is threaded under the steering column so that the switch and adapter can sit under the navigation by the accessory ports.

Development of the Soul Spy app seems to have paused, so in the meantime I am using the Torque Pro app to get OBD readings from my car.

Soul Spy - https://github.com/pemessier/SoulEVSpy

Torque - http://www.mykiasoulev.com/forum/viewtopic.php?f=6&t=471

This thread has also been used in the past for analysing the CANBUS. I am currently looking for the temperatures values for the OBC and a value that shows when the Electric Water Pump comes on. Anyone know? Currently I have to watch the value for the VMCU heatsink temperature and listen to the sound to hear when the heat pump comes on and off. It would be easier to log this automatically if we had the PID codes. What I have found so far is that the OBC heats up quite fast during charging. The EWP comes on at 47C and quickly cools the OBC back down to 35C when it shuts off.

I am using a Konnwei KW902 OBD adapter. I have now added an OBD extension wire with a switch. This solves the possible problems that the KW902 has. 1/drawing power when the car is off. 2/having an insecure password.

Tonsiki OBD 2 Cord 16 pin M/F Male to Female Right Angle Diagnostic Extension Cable with Power Switch to avoid battery drain

I pushed the OBD connector back out of its clip to allow room for the plastic cover to be closed. The OBD extension wire is threaded under the steering column so that the switch and adapter can sit under the navigation by the accessory ports.