Yesterday I had my car in for 3:rd service after 45000 km in 17 months.

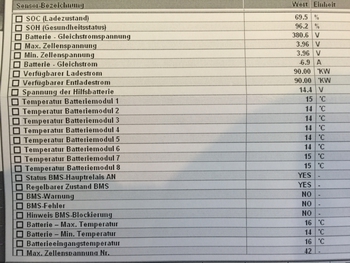

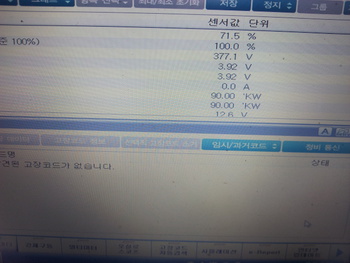

The SOH (State Of Health) value for the high voltage battery had changed. It is now 99.2%

I was hoping to discover a corresponding change in the BMS OBD2 data, but unfortunately there is nothing to find. It's annoying, because the SOH is the only value on the battery report that is not identified in the OBD2 data.

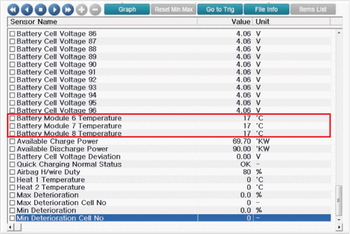

On the other hand, the deterioration values are not present in the battery report, so maybe the SOH is calculated on the fly using some algorithm involving the deterioration values.

My det.values are now: Max 11.5%, Min 10.0%.

Probably need more GDS/KDS readings to figure out the algorithm (if any..) I only had a battery report at 15000 km service, and at that time no OBD2 logging.

Anyone else having other than 100% SOH yet?

The SOH (State Of Health) value for the high voltage battery had changed. It is now 99.2%

I was hoping to discover a corresponding change in the BMS OBD2 data, but unfortunately there is nothing to find. It's annoying, because the SOH is the only value on the battery report that is not identified in the OBD2 data.

On the other hand, the deterioration values are not present in the battery report, so maybe the SOH is calculated on the fly using some algorithm involving the deterioration values.

My det.values are now: Max 11.5%, Min 10.0%.

Probably need more GDS/KDS readings to figure out the algorithm (if any..) I only had a battery report at 15000 km service, and at that time no OBD2 logging.

Anyone else having other than 100% SOH yet?